Rapid Payback of Less than 12 Months

This client is receiving measurable energy savings and realizing the benefits from the Autani networked building controls system. Having obtained a less than 12 month payback on their investment, they are also a strong proponent of not just having the Autani system, but using it to its fullest potential.

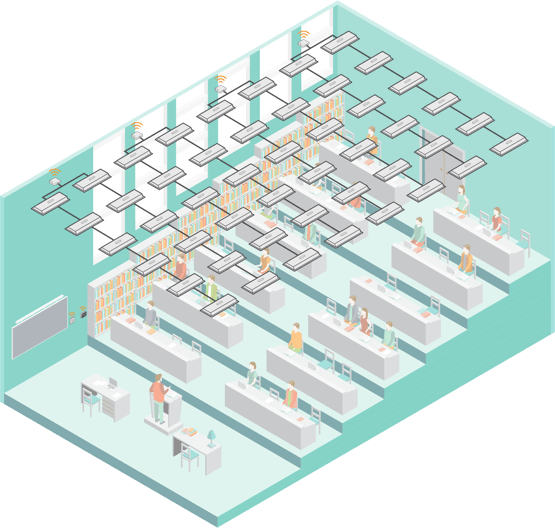

This Automotive Battery Manufacturing Facility actively monitors the use of each controlled area to maintain occupant comfort and safety while maximizing energy savings. Utilizing a combination of tasking tuning and day light harvesting strategies, this Automotive Battery Manufacturing Facility is task tuning their light fixtures to dim at the second and third shifts while still maintaining desired light levels. This facility has also implemented an occupancy-based lighting strategy where the light fixtures are only on if they need to be. They are thrilled that the light fixtures are no longer operating when there is no one in the space. They also rely on Autani to provide them with fixture outage reports. These lighting control strategies are imperative to providing the proper light levels required in this facility to ensure workplace safety and occupant comfort.

Space Optimization + Significant Savings

The Autani system has provided this facility with actionable data, allowing them to determine which areas of their facility were underutilized. Based on this data, they were able to successfully reconfigure their space for maximum optimization. As each manufacturing line was restructured, they were able to easily reconfigure their Autani system, ensuring they maintained their desired light levels.

They have dramatically decreased their energy usage, resulting in a payback of less than 12 months for the complete design, purchase, and installation of the Autani system. The Autani system alone—without factoring any energy savings from converting to LED lighting—is currently saving this client 41.3% of energy used in this Automotive Battery Manufacturing Facility.